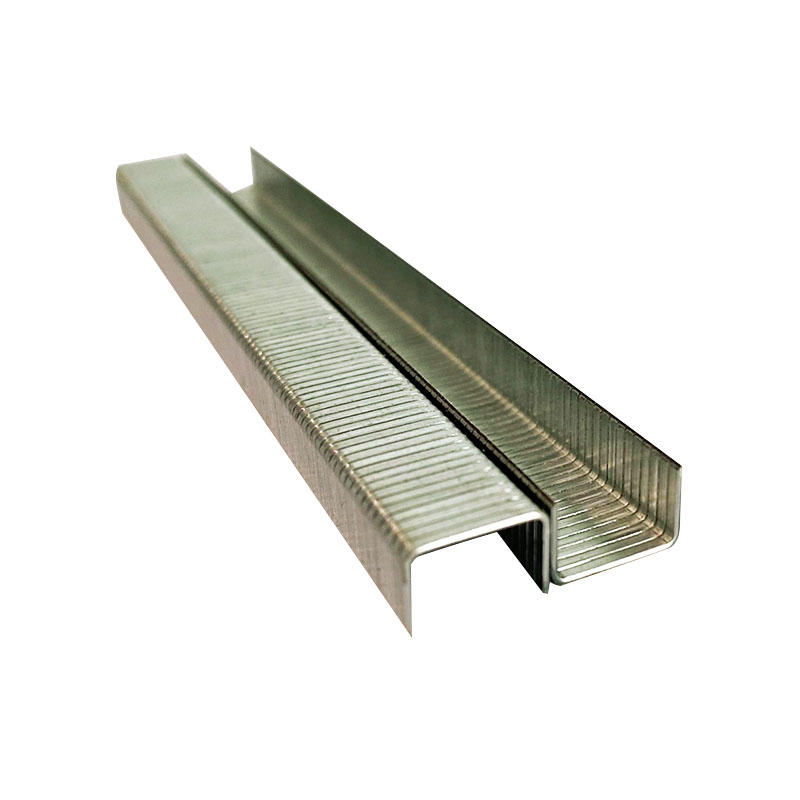

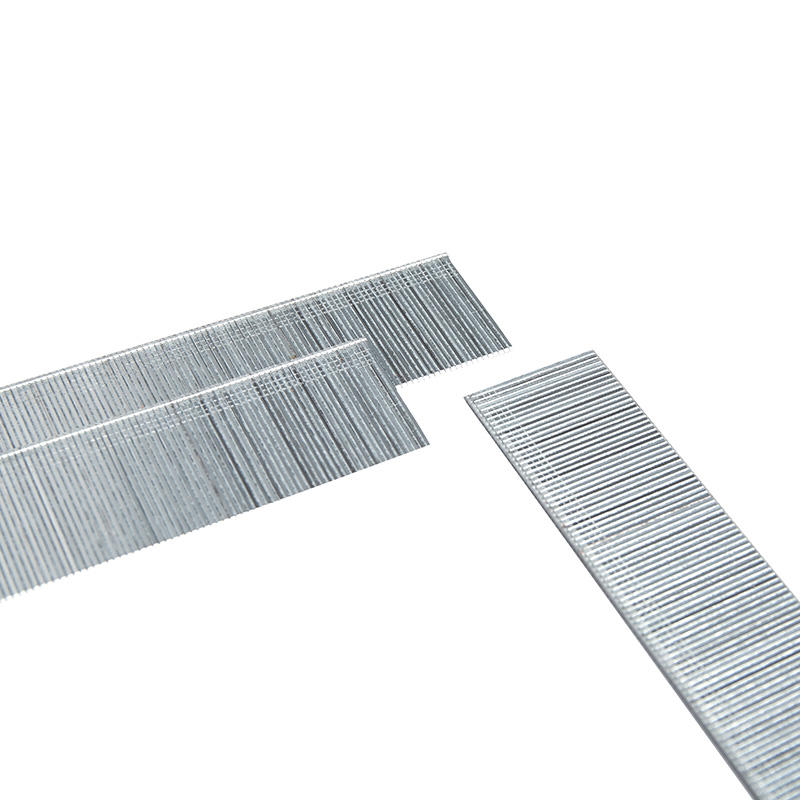

Heavy Wire Staples are a common tool used in construction, furniture, industry and other fields. However, their corrosion resistance is often poor. This is mainly because Heavy Wire Staples are usually only subjected to simple anti-corrosion treatment, and their surface is easily corroded by oxygen, moisture, acids and alkalis in the air, resulting in oxidation reaction and rust on the nails.

Oxygen in the air is one of the main causes of rust on nails. The oxide layer formed on the surface of the nails is not stable and is easily oxidized by oxygen to form red rust. This will lead to a decrease in the strength of the nails, thus affecting their service life and bearing capacity.

Moisture is also an important factor leading to rust on nails. Nails are easy to absorb moisture in humid environment, which makes the surface in a wet state, thus promoting the oxidation reaction. Especially when there are salt or other impurities in the water, it is easier to accelerate the rusting process of nails. This is why nails are easy to rust in coastal areas or places with high humidity.

Acid and alkali chemicals can also corrode nails. When nails are exposed to acid rain, acidic soil, alkaline detergent and other environments for a long time, the acid and alkali substances in them will corrode the surface of nails. This chemical reaction will destroy the surface layer of the nails, making the nails more prone to oxidation reaction and rust.

In order to improve the corrosion resistance of Heavy Wire Staples, some measures can be taken for protection. A common method is to galvanize the nails. Galvanizing can form a zinc layer on the surface of the nails, which plays an isolating and protective role, and improves the corrosion resistance of the nails. In addition, nails can be sprayed or coated with a special anti-corrosion coating to form a protective film, preventing nails from direct contact with air, moisture, acids and alkalis.

In the process of use, some preventive measures can also be taken to prolong the service life of Heavy Wire Staples. For example, try to avoid exposing nails to humid environment, clean and maintain them regularly, and repair or replace rusty nails in time.

The corrosion resistance of Heavy Wire Staples is generally poor, mainly because their surface is easily corroded by oxygen, moisture, acids and alkalis in the air, resulting in oxidation reaction and rust on the nails. Therefore, it is necessary to take some protective measures, such as galvanizing, spraying anti-corrosion coating, etc., to prolong the service life of nails. At the same time, in the process of use, we should also pay attention to avoid nails from being exposed to humid environment for a long time, and regularly maintain and replace them to keep their good working condition.